Why Maintenance Matters for Sublimation Printers

Picture this: a rush job comes in, your client needs vivid, perfect prints by tomorrow — and your printer sputters out with streaks. That sinking feeling? We’ve all been there.

Printer maintenance might not be glamorous, but it’s the unsung hero of every reliable, high-quality sublimation business. This guide brings you everything you need to keep your Sawgrass SG500 or SG1000 running like a pro - whether you’re starting your side hustle or managing a full-scale shop.

Let’s make printer upkeep simple, repeatable, and worth it.

Every flawless, full-color transfer starts with something less flashy: printer maintenance. If you’ve dealt with banding, streaks, or an unexpected clog before a big job, you know how easily things can go sideways.

This guide brings everything you need to keep your Sawgrass printer in peak shape, whether you’re just getting started or running a full production setup. Think of it as your go-to resource for keeping things flowing—literally and creatively.

Here’s what we’ll cover:

- Daily, weekly, and monthly maintenance routines

- The 3 habits that prevent 90% of printing headaches

- Easy fixes for common sublimation issues

- Smart tips for running a smoother print shop

- The 3 Core Maintenance Habits for Sawgrass Printers

- Think of these as your “maintenance musts”—skip them at your own risk:

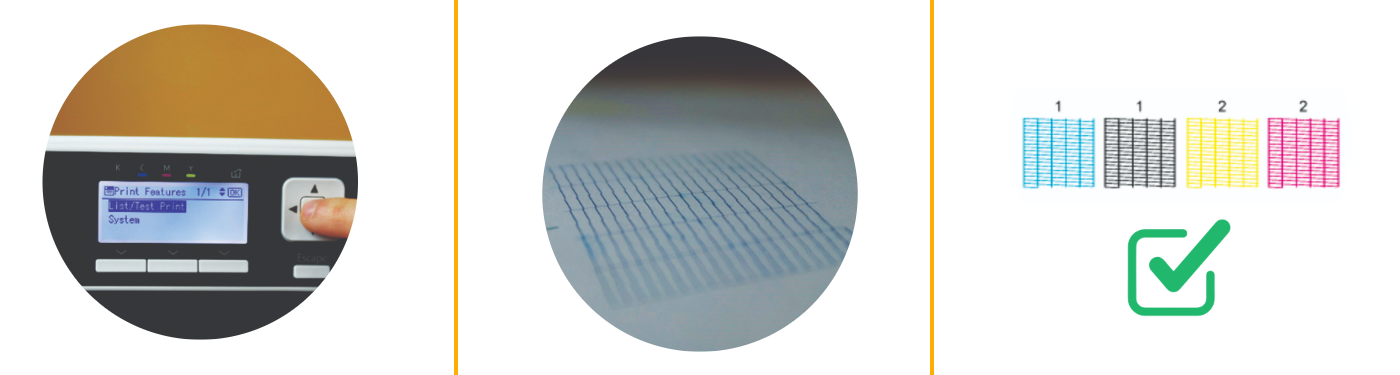

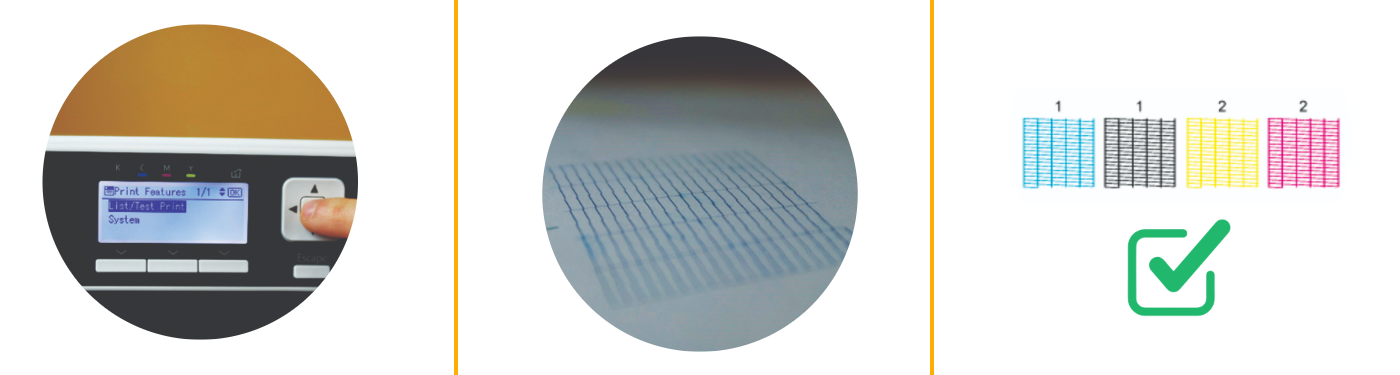

Run Nozzle Checks

Before every print session or after a few idle days, do a quick nozzle check. It takes one minute and can save you hours of frustration. You’re looking for clean, complete lines. If you see gaps or missing sections, it’s time to clean.

Learn how to do it right → How to Run Nozzle Checks for SG500 & SG1000

- Use Print Head Cleaning (Only When Needed)

- Don't go overboard. A light clean helps clear small clogs, but every cleaning uses ink and fills your waste tank. Only do it if the nozzle check tells you something's off. Don't go overboard. A light clean helps clear small clogs, but every cleaning uses ink and fills your waste tank. Only do it if the nozzle check tells you something's off.

- Flush When You’re Desperate

- Flushing sends a heavy ink flow to clear stubborn clogs—but it should be a last resort. Useful after a long break or when multiple cleanings fail.

- Pro Tip: Always check your waste ink tank after flushing. Overflow = big problems.

Your SG500/SG1000 Maintenance Routine (Daily, Weekly, Monthly)

Daily Tasks

- Run a nozzle check (1 min)

- Cover the printer when not in use

- Print a quick swatch (test print) to keep colors flowing

Weekly Tasks

- Check the belt for any paper debris or damage.

- Check for leaks or ink level dips

- Give the exterior a quick clean

- Print a test gradient to monitor output quality

Monthly Tasks

- Perform a manual head cleaning if needed

- Inspect the waste ink tank

- Check for firmware updates or Print Software Updates

Grab our Printable Maintenance Checklist — it includes a daily, weekly, and monthly schedule, tool recommendations, and a quick log sheet to help you track each step. Never miss a critical task again!

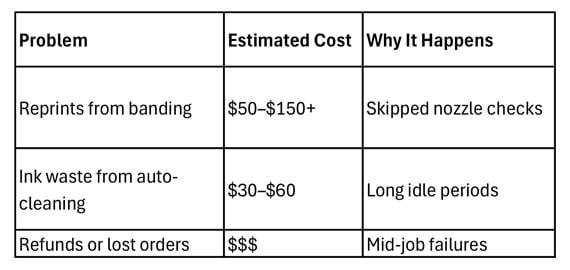

How Routine Maintenance Saves You Time, Ink & Money

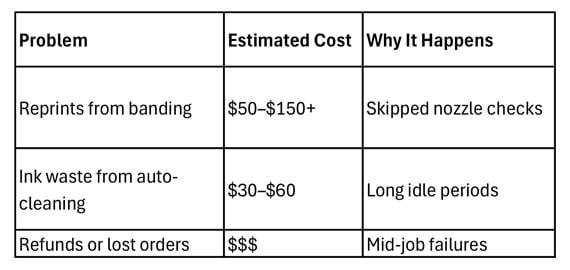

Skipping the basics might seem harmless—until your prints start failing.

Just a few minutes a day can prevent most of these issues—and keep your production smooth.

Shop Maintenance Supplies -

Troubleshooting & Common Sublimation Issues

Here’s a look at the most common sublimation problems and how to fix them:

- Ghosting – Caused by shifting during transfer. Secure the paper with thermal tape, or adhesive spray.

- Banding – Usually from nozzle clogs. Run a nozzle check first.

- Dull or faded prints – Often due to low pressure or incorrect time/temp settings.

- Wrong colors – Check your Color Profiles and ink levels.

Want more? Read: 7 Common Sublimation Issues & How to Fix Them

Tips to Maximize Sublimation Success

A well-maintained printer is only half the battle. Here’s how to stay sharp:

- Maintain a stable workspace temp (no humidity swings)

- Use top-grade paper and ink

- Store printed sheets flat and dry, in a cool environment

Need more? Check out: 7 Tips for Sublimation Success

Choosing the Right Sawgrass System for Your Needs

Maintenance isn’t one-size-fits-all. Here’s a quick comparison:

- SG500 – Great for beginners or light production. Max print size: 8.5" x 14" / 8.5" x 51" (with Bypass Tray)

- SG1000 – Built for high-output, scalable workflows. Max Print size: 11" x 17" / 13" x 19" or 13" x 51" (with Bypass Tray)

Not sure which is right? Read: Which Sawgrass Sublimation System is Right for You?

Frequently Asked Maintenance Questions

Why is my Sawgrass printer printing lines?

A: This is usually caused by clogged print heads or dry nozzles. Run a nozzle check through the Sawgrass Print Utility. If the print test shows broken or missing lines, follow up with a head cleaning. Avoid multiple cleanings in a row as this can waste ink.

Why is my Sawgrass printer printing dull colors?

A: Dull sublimation prints often result from clogged nozzles, expired ink, or incorrect print settings. First, run a nozzle check and clean the heads if needed. Also, confirm you’re using the correct profile (Printing via Print Utility), sublimation paper, and heat press settings.

How do I clean the print heads on a Sawgrass SG500/SG1000?

A: On the printer go to Menu > Printer Features > List/Test Print > Head Cleaning > Select Head 1 or Head 2. Or, open Sawgrass Print Utility, navigate to Devices > Printer Utilities > Head Cleaning, and follow the prompts. Perform a nozzle check afterward. For persistent issues, consider a manual clean with a lint-free swab and approved cleaning solution.

How do I empty the Sawgrass SG500/SG1000 waste ink collection unit?

A: The SG500/SG1000 has an internal waste tank that tracks ink usage, this tank can be easily removed and replaced from the Ink Compartment, when full. Once full, the printer displays a message. Purchase a new tank from Coastal Business Supplies to avoid job delays.

PRO Tip: Always keep an extra waste unit on hand!

How long does Sawgrass ink last in the printer?

A: Ink cartridges generally last 12–18 months when stored and used properly. To prevent drying or clogs, print regularly or run a small test print every few days.

Can I refill Sawgrass SG500/SG1000 ink cartridges?

A: No. Sawgrass uses sealed, chip based single-use cartridges and does not support refilling. Using refilled cartridges can lead to clogs, color issues, and void your warranty.

How do I reset a Sawgrass ink cartridge?

A: You can't. Sawgrass cartridges are chip-locked and non-resettable. Replace with new, genuine cartridges when they run out.

Why is my Sawgrass printer offline?

A: Check if the printer is powered on and connected via Wi-Fi or USB. Reconnect it in Sawgrass Print Utility under 'Printers & Devices'. Restart the printer and your computer if needed.

How do I get my Sawgrass printer back online?

A: Go to Sawgrass Print Utility and ensure the printer is detected. Reconnect via Wi-Fi or plug in the USB. If offline, restart both devices and try reconnecting.

Can I use third-party or non-Sawgrass ink in my SG500 or SG1000 printer?

A: No. Sawgrass printers are designed to work exclusively with genuine Sawgrass ink cartridges. Using third-party or refilled ink can result in severe consequences:

- The printer may display warnings or errors

- It may shut down entirely

- In some cases, it will print an X pattern over your designs, making prints unusable

Additionally, using non-genuine ink voids your warranty and can permanently damage the print head or internal components. To protect your investment and ensure consistent, high-quality results, always use original Sawgrass ink.