Sublimation FAQ

Looking for Product Instructions? Templates?

Product instructions and product templates will be located on the product page of the SKU purchased. Instructions can be found under the "Product Instructions" tab, and templates can be found under "Downloads".

What is Dye-Sublimation?

Dye sublimation is a digital heat transfer process that transfers an image to a polyester garment or polyester coated substrate permanently. When heated to a high temperature, sublimation ink turns into a gas, allowing it to enter into the open pores of the polyester-coated item or polyester garment. Once the transfer paper is removed, the pores of the item cool and close up, trapping the ink (and image) inside the surface of the item. The sublimated image is a permanent application and will take on the texture and base color of the substrate.

This process works only on white or very light garments and substrates. Cotton fabric or items that have not been specifically coated for this process are not compatible with sublimation. All our sublimation blanks have been factory coated with sublimation polyester coating formulated specifically for this type of transfer process.

Dye sublimation requires the following to get started:

- Sublimation printer

- Sublimation ink

- Color profile to correct color output from printer to paper to final substrate

- Sublimation paper

- Heat press machine or silicone wraps (for drinkware)

- Sublimation blanks or 100% white/light polyester garments

What Do I Need to Start A Sublimation Business?

Starting a sublimation business is one of the easiest and most economical start-ups in the digital decorating industry.

- Sublimation compatible printer - You must have a dedicated sublimation printer that is compatible with the available cartridges. Currently, these include Sawgrass & Epson small format printers and a wide variety of large format printers such as, Epson, Mimaki & Mutoh.

- Sublimation inks - Sublimation inks aren't quite the same as standard inkjet ink - they are available in the usual cartridge form, or in some cases, bulk ink liters. Sublimation ink must be heat activated for the colors to fully brighten and transfer into the item due to the chemical make-up of the ink. Because it is different from standard inkjet ink, you must use a specialized printer driver, software, or color profile embedded within the document for correct output. This is something that the manufacturer of the ink can develop and provide, which is why it is important to buy dye-sublimation ink from a quality supplier.

- Sublimation paper - Sublimation paper is necessary for the ink to transfer onto the substrates; it is designed to release as much of the printed image as possible from the sheet, when heated and transferring to a polyester coated item, or polyester fabric.

- Heat press or silicone press wraps - Since sublimation requires such a high level of temperature and pressure, you must use either a heat press to press the item or a silicone wrap within a conventional oven to press the item. A commercial heat press will be the most efficient way of sublimating most of our items, but some items with a unique shape such as the pet bowls and shot glasses must be sublimated using a wrap in a conventional oven.

- Color correction software or color profile - Since sublimation ink is not the same as the intended inkjet ink for the printers it often runs through some form of correction for the color differences that are needed. Most printers that are made for Sublimation offer this type of color correction program/driver.

- Sublimation blanks - Sublimation blanks are items that are specifically coated to receive sublimation ink. With sublimation you can transfer onto 100% white polyester fabric or fabric-topped items, as well as poly coated hard surfaces. You cannot sublimate onto cotton or dark fabrics -- colored garments can be sublimated onto but bear in mind that since the ink is slightly transparent, your transfer/image will take on the shade of the shirt color below it, and may result in a poor result. There are sprays on the market designed for home users to coat their own items to be sublimated upon, but in our testing, we have not found the results to be consistent in coverage or durability.

Why are my Transfers Browning?

If your transfers are browning, then this is an issue with Over-pressing.

Over-pressing can be caused by a couple of factors that will be detailed below.

- Time: One of the most occurrences of over-pressing is too much time. Double check the time we suggest for that item.

- Pressure: Too much pressure can place a lot of heat on to the surface of the item and cause it to scorch. If time and temperature are correct, try and reduce the pressure.

- Temperature: If the temperature of the press is off and running hotter than it is currently reading then it will cause browning. To double check this we suggest using heat test strips to get a better idea as to what your platen is actually heating to.

Why are my Transfers Coming Out Blurry?

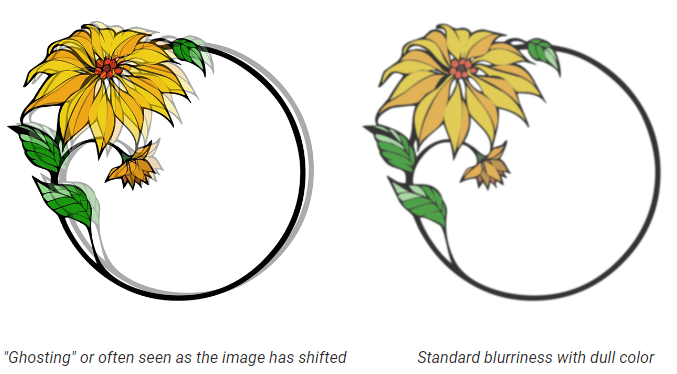

When pressing sublimation blanks, one of the most common issues is blurry results. Blurriness can manifest itself in two different ways: in the form of a duplicate image also called "ghosting" which looks a lot like seeing double or an image that has reduced detail.

Ghosting

During the pressing process, an image may shift position on the substrate causing the sublimation ink to continue imprinting but in a different spot. This most often occurs when the heat press machine is opened and the top platen picks up, or accidentally moves, the printed image on the sublimation paper while the sublimation process is still going on. This is avoided easily by taping down the design securely onto your substrate with heat transfer tape so that it doesn't shift at any point. For some items like polyester apparel, a spray adhesive may be a better solution as tape doesn't stick to it easily.

Remember that if the substrate is still hot, the sublimation ink from the paper will continue to activate. If you pre-press your sublimation blanks, ensure that they are cool to the touch before lining up your printed transfer for pressing.

Blurry, Dull Image

The second reason why your image might be coming out blurry, especially if there is a loss of detail and a change in color (looking yellow or dull), is over-pressing. Over-pressing can be caused either due to too much heat or too much time. A blurry, dull image is the most common sign of pressing your sublimation blanks for too long or with too much heat. Simply decreasing the time usually resolves the problem.