Performing regular nozzle checks for Sawgrass SG500 & SG1000 printers is crucial in maintaining consistent print quality and extending the life of your sublimation printer. Whether you're printing vibrant apparel or customized mugs, a quick nozzle check can save you from ruined prints and wasted materials.

When nozzles become clogged, it can lead to visible issues like streaks, faded areas, or incorrect colors—frustrating results that impact your professional output. Clogged printhead issues are often the root cause of these symptoms.

However, there is good news about all of this! Regular printer maintenance like nozzle checks and head cleanings helps avoid costly downtime and potential repairs. This guide is perfect for beginners and will walk you through everything you need to know about Sawgrass SG500 and SG1000 troubleshooting through effective nozzle checks.

Understanding Nozzle Checks

What is a Nozzle Check?

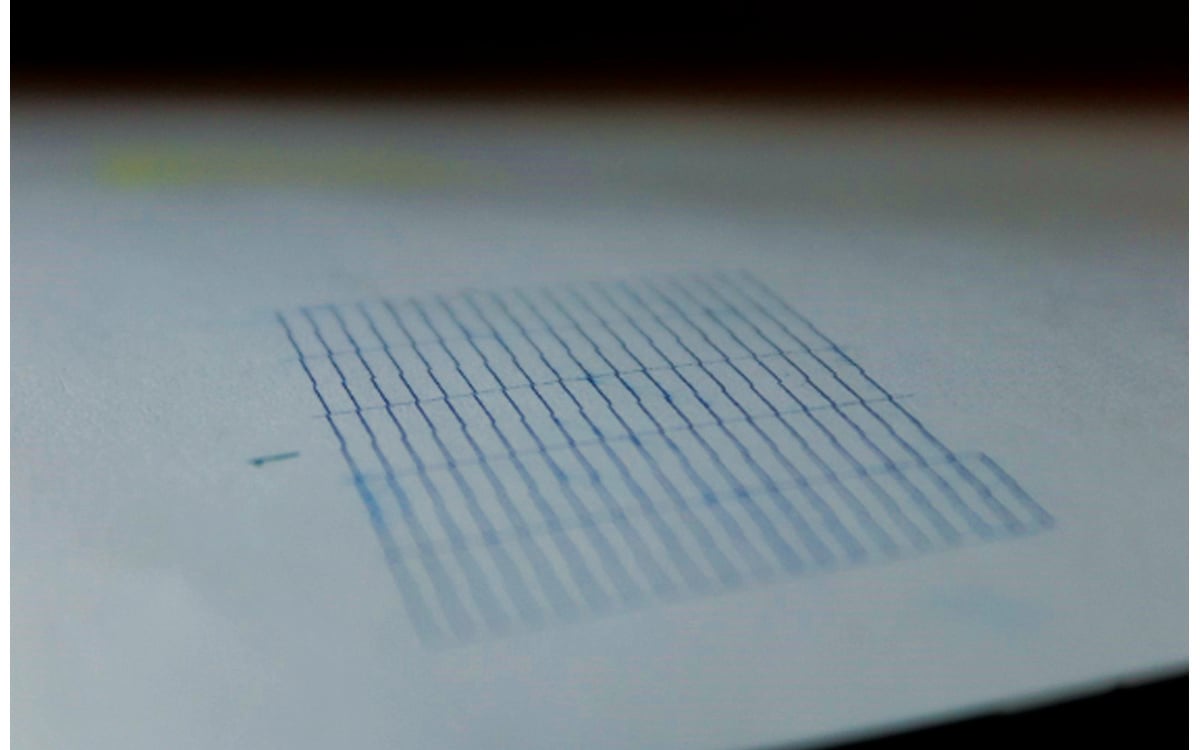

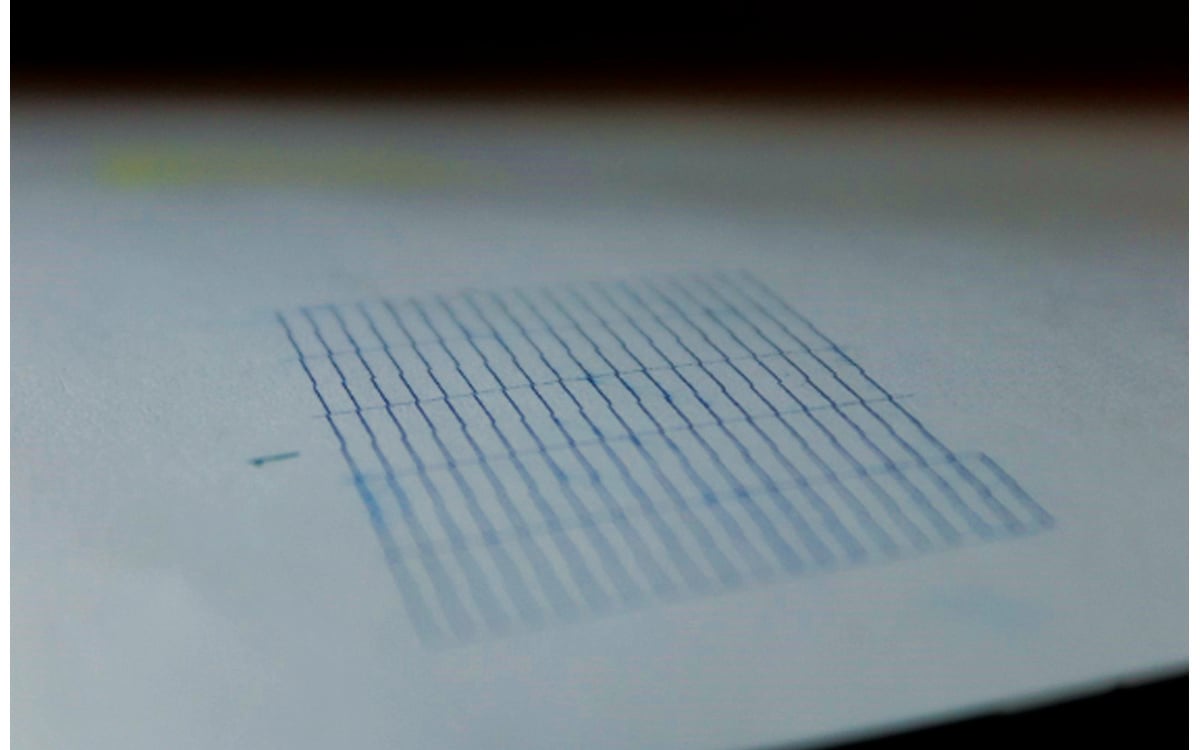

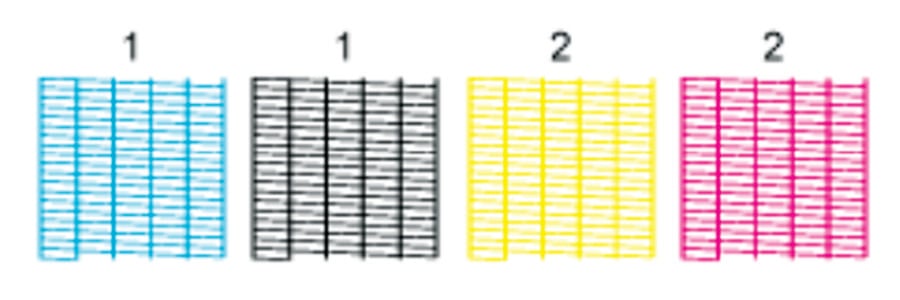

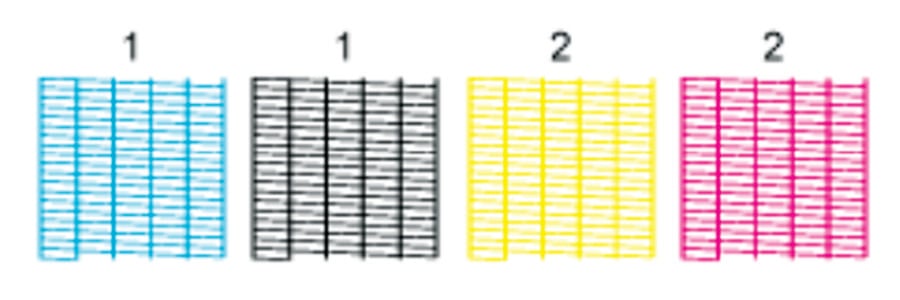

- A nozzle check is a diagnostic test your Sawgrass printer performs to verify that all ink nozzles are firing correctly. This quick printout displays a patterned grid for each ink color, giving you visual confirmation of your printhead’s health.

- It’s a key part of printhead diagnostics and identifies any blockages or irregularities before they turn into bigger print quality problems.

Importance of Regular Nozzle Checks

- Running a nozzle check once a week or before major print jobs ensures your colors stay true and your lines stay crisp. Even better? You don’t need to use expensive sublimation paper—plain copy paper works perfectly for this routine check.

- This small effort supports your overall Sawgrass printer maintenance guide and extends the life of your printer.

Tip: Bookmark our printer maintenance essentials guide to keep your SG500 or SG1000 running like new.

Step-by-Step Guide to Performing a Nozzle Check

Using the Printer Control Panel

Step 1. Press the [Menu] button.

Step 2. Navigate to [Printer Features] and press [OK]

Step 3. Select [List/Test Print] and press [OK].

Step 4. Choose [Nozzle Check Pattern] and press [OK].

Step 5. Press the selection button for [Print].

Using Sawgrass Print Utility

Steps to perform a nozzle check via the software:

- Open Sawgrass Print Utility.

- Navigate to the 'Devices' tab.

- Select your printer and click on 'Printer Utilities'.

- Choose 'Nozzle Check' and follow the prompts

Interpreting Nozzle Check Results

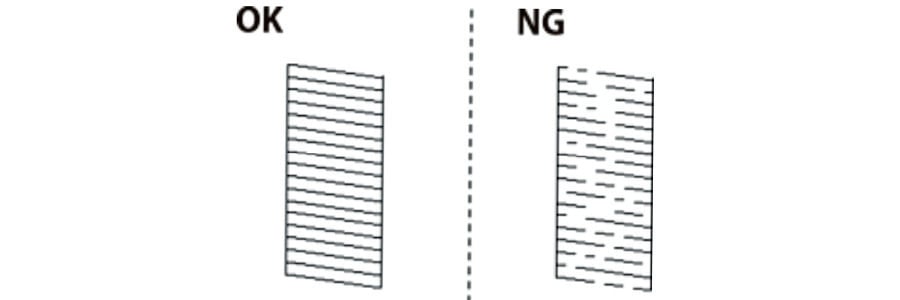

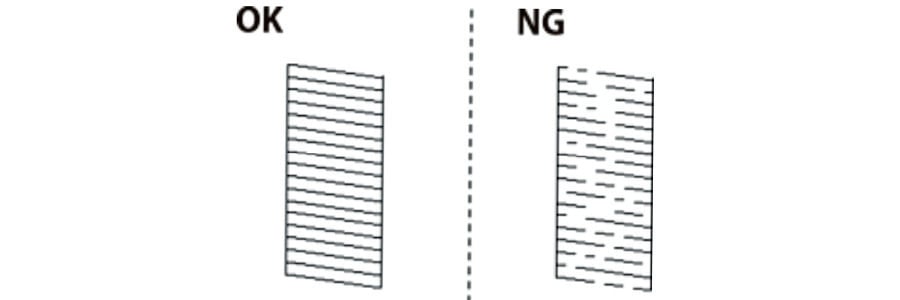

Ideal Nozzle Check Pattern

A perfect SG500/SG1000 nozzle check pattern features clean, uninterrupted lines in black, cyan, magenta, and yellow. Each line should be evenly spaced with no fading or gaps—this confirms that ink is flowing correctly through each nozzle.

Identifying Issues

If your nozzle check doesn’t look ideal, here’s what to watch for:

- Missing lines indicate clogged nozzles that need cleaning.

- Faded lines suggest partial clogs.

- Incorrect colors: A mismatch in tones could suggest ink delivery issues or even a software problem with Sawgrass Print Utility.

Troubleshooting Common Issues

Performing a Head Clean

When you detect missing or faded lines, start with a printhead cleaning:

- Access the [Menu] on the printer.

- Navigate to [Printer Features] > [List/Test Print] > [Head Cleaning].

- Select the appropriate head (Head 1 for Cyan and Black; Head 2 for Magenta and Yellow).

- Press [OK] to start the cleaning process.

Performing a Head Flush

If multiple head cleans don’t resolve the issue, perform a head flush—a more intensive cleaning:

- Access the head flush function via the printer’s Maintenance (steps above) menu or through Sawgrass Print Utility.

- Follow on-screen steps to initiate the flush.

- Only perform when necessary, as frequent flushing can use a significant amount of ink.

Cleaning the Capping Station

The capping station can collect dried ink and debris, affecting nozzle performance. To clean:

- Power off the printer.

- Use warm distilled water and a lint-free cloth to gently clean the sponge and surrounding area.

- Avoid using tap water or alcohol, as these can damage printer components.

Coastal how-to clean your capping station video: HERE

Preventative Maintenance Tips

Keep the Printer Powered On

- Your Sawgrass SG500 or SG1000 runs automatic printer maintenance cycles periodically—but only when it’s powered on. Leaving the printer off for extended periods increases the risk of clogs.

Regular Printing

- Printing at least once a week—even a small test page—keeps ink flowing and prevents dried nozzles.

Use Genuine Sawgrass Inks

- For best results, always use authentic Sawgrass inks. Third-party cartridges can introduce inconsistencies in ink flow and damage your printer over time.

Frequently Asked Questions

Q1: How often should I perform a nozzle check?

A: It's recommended to perform a nozzle check weekly or before starting a large print job.

Q2: Can I use regular paper for nozzle checks?

A: Yes, plain copy paper is sufficient for nozzle checks.

Q3: What should I do if the nozzle check pattern shows missing lines?

A: Perform a head cleaning. If issues persist, consider a head flush or contact Sawgrass support.

Q4: Why is my printer not printing the correct colors even after a successful nozzle check?

A: Ensure you're using the correct color profiles and genuine Sawgrass inks. Also, check for any software updates.

Q5: How do I clean the capping station?

A: Use warm distilled water and a lint-free cloth to gently clean the capping station sponge.