- Same-day Shipping / Before 7PM cst

- Free Shipping +$199

- Need Competitive Bulk Pricing?

Heat Press Machines

A heat press is an essential tool in the arsenal of anyone involved in the custom apparel and merchandise industry. From small-scale crafters creating unique designs from home, to small businesses producing custom items, all the way to enterprise-level production houses handling large volumes, a heat press plays a pivotal role. It's used to apply designs on fabrics and other materials using heat and pressure. This guide will delve into the various types of heat presses available, helping you understand which one fits your needs, and provide essential buying tips to ensure you make the best investment possible.

Types of Presses

Clamshell Heat Presses

Clamshell heat presses are named after their design, resembling a clamshell where the top platen opens upwards from the bottom platen. They are particularly favored for their ease of use and space-saving design, making them perfect for beginners or those with limited workspace.

Pros: Compact, easy to operate, quick to heat up.

Cons: Limited in terms of the material thickness they can handle.

Best Use: Ideal for t-shirts and flat garments.

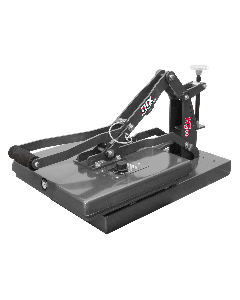

Swing-Away Heat Presses

Swing-away heat presses allow the top platen to swing away completely from the lower platen. This design provides better access to the layout area, reducing the chances of accidental contact with the heat.

Pros: Suitable for a variety of material thicknesses, safer for the user.

Cons: Requires more space than a clamshell as the top platen swings to the side.

Best Use: Excellent for projects requiring precise placement and for use with thicker materials.

Drawer Heat Presses

Drawer heat presses feature a design where the lower platen can be pulled out like a drawer, allowing users to layout their materials without reaching under the heated upper platen.

Pros: Enhances safety, makes it easier to arrange and remove items.

Cons: Can be more expensive and still require space similar to swing-away presses.

Best Use: Great for those prioritizing safety and ease of use, especially in busier or more constrained environments.

Industrial Heat Presses

Industrial heat presses are essential for imprinting designs on fabrics and larger materials. They are highly efficient, providing consistent results and are excellent for large-scale production.

Pros: Extremely versatile, offering more services to clients.

Cons: More complex to operate and usually more costly.

Best Use: Fashion, apparel and home decor fabrics, as well as sublimation products that require high-quality, quick production capabilities.