How to Select the Right Equipment for Your Sublimation Project

Sublimation printing is a fantastic way to transfer bright, long-lasting designs onto various materials, from t-shirts to mugs and more. Whether you’re a hobbyist or running a small business, choosing the right sublimation equipment is crucial to achieving professional results. With so many options available, selecting the best tools for your needs can be overwhelming. This guide will help you make informed decisions when choosing the right equipment for your sublimation project.

Understanding the Basics of Sublimation Printing

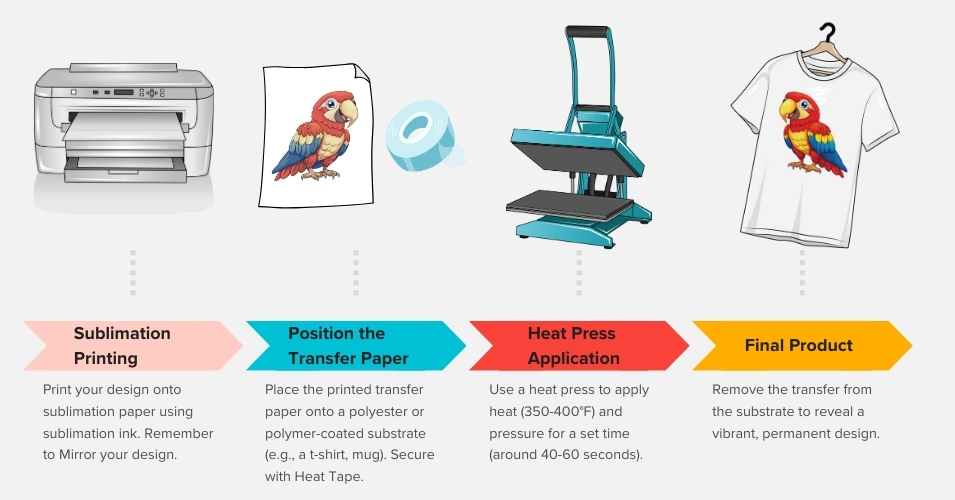

Before diving into equipment selection, it’s essential to understand how sublimation printing works. Sublimation uses heat to transfer dye onto materials that either have a special coating or are made from polyester. The process requires a sublimation printer, sublimation inks, a heat press, and appropriate substrates. For more detailed information on how sublimation works, click here.

1. Choosing the Best Sublimation Printer

The printer is the heart of your sublimation setup, so it’s important to choose the right one. Consider factors like the printer’s size and compatibility with sublimation inks. Here’s a breakdown of two types of sublimation printers to help you make the right choice.

Desktop Sublimation Printers

- Ideal For: Home-based projects and small-scale production

- Benefits: Affordable and space-efficient; suitable for small items like mugs, t-shirts, and accessories

- Considerations: Limited print size, so it may not be suitable for larger designs

-

Epson SureColor F570 Pro 24" Desktop Sublimation PrinterSpecial Price $2,745.00 Regular Price $2,995.00

Epson SureColor F570 Pro 24" Desktop Sublimation PrinterSpecial Price $2,745.00 Regular Price $2,995.00

Wide-Format Sublimation Printers

- Ideal For: Larger projects and high-volume production

- Benefits: Versatile and capable of handling a wider range of substrates and larger designs

- Considerations: Higher cost and space requirements, but worth the investment for commercial use or upgrading from a small format printer.

-

Epson SureColor F6470 44" Production Edition Sublimation PrinterSpecial Price $7,695.00 Regular Price $8,195.00

Epson SureColor F6470 44" Production Edition Sublimation PrinterSpecial Price $7,695.00 Regular Price $8,195.00 -

Epson SureColor F6470H 44" Production Edition Sublimation PrinterSpecial Price $8,195.00 Regular Price $8,695.00

Epson SureColor F6470H 44" Production Edition Sublimation PrinterSpecial Price $8,195.00 Regular Price $8,695.00 -

Epson SureColor F9570 64" Dye-Sublimation PrinterSpecial Price $27,995.00 Regular Price $29,995.00

Epson SureColor F9570 64" Dye-Sublimation PrinterSpecial Price $27,995.00 Regular Price $29,995.00 -

Epson SureColor F9570H 64" Dye-Sublimation PrinterSpecial Price $32,995.00 Regular Price $34,995.00

Epson SureColor F9570H 64" Dye-Sublimation PrinterSpecial Price $32,995.00 Regular Price $34,995.00

2. Selecting Sublimation Inks

Quality inks are essential for vibrant, long-lasting prints. Selecting the right ink can make a big difference in the quality and longevity of your prints. If you're using a dedicated sublimation printer, such as the Epson F170/F570 Pro or Sawgrass SG500/SG1000, the correct sublimation ink is typically included with your printer purchase when you buy from an authorized dealer. This ensures that your inks are optimized for use with your printer and will deliver consistent results.

Although we do not recommend converting your own printer, If you’ve chosen to convert a standard printer (like the Epson EcoTank series) for sublimation use, you'll find a range of third-party sublimation ink options at various price points. These inks are widely available online, including on marketplaces like Amazon. When choosing sublimation inks, consider:

- Quality: Opt for high-quality inks from reputable brands to ensure rich, vivid colors.

- Color Range: If color accuracy is crucial for your projects, choose inks with a broad color spectrum to get true-to-life colors.

3. Investing in the Right Heat Press for Sublimation

A heat press is vital for transferring designs to your substrate. The type and size of the heat press you need depend on the items you’re creating. Types of heat presses to consider:

Clamshell Press: Simple and Compact, Great for Beginners

Why it’s great for sublimation:

- Compact & Space-Saving: Clamshell presses are generally compact and take up minimal space, making them ideal for home or small workspace environments. If you're just starting with sublimation, this is a great entry-level option.

- Ease of Use: The simple open-and-close motion makes it beginner-friendly, with minimal learning curve.

Potential drawbacks:

- Limited Access: The clamshell design provides less space for arranging or aligning your sublimation transfers, especially on larger items. This can be challenging when you need precise placement.

- Risk of Burns: Since the top platen remains close to the bottom when you open the press, it increases the risk of burns or accidental contact with the hot surface.

- Pressure: Since the top platen remains at an angle, when closing the press, the back of the heat press gets more pressure than the front, making it difficult to get an even press on rigid substrates.

Swing-Away Press: Offers More Space and Reduces the Risk of Burns

Why it’s great for sublimation:

- Better Alignment: With the top platen swung away, you have full access to the working area. This is a significant advantage when you need to position your transfer precisely on larger or more complex items, like sublimation plaques, metal sheets, or bulky fabrics.

- Even Pressure Distribution: Swing-away presses tend to distribute pressure more evenly, which is crucial for achieving flawless sublimation prints without areas of uneven color.

- Safety: Since the hot platen moves completely away from the work area, the risk of burns is significantly reduced, making it safer to handle and align heat-sensitive substrates.

Potential drawbacks:

- More Space Required: The swinging action requires more space around the press, so it may not be suitable for cramped workstations.

- Slight Learning Curve: Although not overly complicated, the swing-away design may take a little more time to get used to compared to the simpler clamshell press.

Draw-Style Press: Easier Item Placement and More Precision

Why it’s great for sublimation:

- Full-Access Workspace: Like the swing-away, the draw-style press allows for precise placement of your designs. Since the lower platen can be pulled out, you have clear access to adjust and align the substrate without the upper platen hovering above.

- Precision & Flexibility: This design offers a highly precise workflow, making it great for detailed sublimation projects where proper alignment is key. It's also easier to work on thicker or multi-layered items, like puzzles, or even pressing multiple smaller items at once.

Potential drawbacks:

- Space & Cost: Similar to the swing-away, the draw-style press requires additional space to accommodate the sliding lower platen. These presses also tend to be on the more expensive side, which may be a factor for beginners or hobbyists.

- More Moving Parts: With a sliding lower platen, there's a chance for more wear and tear on the press over time, although high-quality presses minimize this concern.

Consider the size of the platen, as larger items like blankets or banners need a bigger press. Look for models with accurate temperature and pressure controls to ensure consistent, high-quality transfers.

4. Choosing Sublimation Substrates

Sublimation requires specific materials that can bond with the dye through heat. Here are some common substrates and tips for choosing the right ones:

- Apparel: Best results are achieved on 100% polyester or high-polyester blends. Sublimation works best on white or light-colored fabrics.

- Mugs: Choose sublimation mugs with a high-quality polymer coating for vibrant designs.

- Home Decor Items: Make sure items like coasters and mousepads have a smooth surface and a polymer coating for optimal color transfer.

5. Additional Sublimation Supplies

Don’t forget the smaller essentials that make a big difference in your workflow:

- Heat Resistant Tape: Keeps your design in place during pressing.

- Protective Paper: Prevents ink from bleeding onto your heat press.

- Cleaning Supplies: Regular maintenance of your printer and heat press will ensure they keep working smoothly.

6. Budget Considerations

Your budget plays a major role in choosing sublimation equipment. While investing in high-quality equipment can save you money in the long run, there are affordable options for beginners or those working on smaller projects. Look for entry-level models that offer reliable performance or consider refurbished equipment to stretch your budget.

-

Epson SureColor F570 Pro 24" Desktop Sublimation PrinterSpecial Price $2,745.00 Regular Price $2,995.00

Epson SureColor F570 Pro 24" Desktop Sublimation PrinterSpecial Price $2,745.00 Regular Price $2,995.00

Selecting the right sublimation equipment—printer, inks, heat press, and substrates—is key to producing high-quality, professional results. Whether you're just starting or upgrading your setup, understanding your specific needs and aligning them with your budget will ensure you create stunning, customized items that are sure to impress.

At Coastal Business Supplies, we’re here to help you every step of the way. Our Customer Success team can answer any questions or provide expert guidance as you build your sublimation setup. Whether it’s troubleshooting, product recommendations, or tips on getting the most out of your equipment, we’ve got you covered. Your success is our priority—and with the right equipment and support, you’ll be ready to take your sublimation projects to the next level.

Happy Sublimating!

-

Decorating With TheMagicTouch CPM 6.2 Hard Surface Heat Transfer Paper

Sep 4, 2018Is is possible to use this transfer paper on...

- Sublimation

- heat transfer vinyl

- business tips

- vinyl

- christmas

- holidays

- gifts

- rebrand

- direct-to-garment

- pretreatment

- mug press

- how-to

- sign vinyl

- holiday

- Artesprix markers

- HTV

- Siser

- father's day

- gift ideas

- fourth of july

- promotional products

- artesprix

- sublimation markers

- award plaques

- heat transfer paper

- cpm 6.2

- OKI

- white toner

- laser transfer paper

- Mothers Day

- Entrepreneur

- Mompreneur

- Challenges

- dtg

- DTF

- epson

- Crio

- White Toner Transfer

- Laser

- Welcome

- Sales

- Beginner

- Getting Started

- Dye-Sub

- T-Shirt

- Startup

- Printers

- Heat Presses

- Heat Transfers

- Sublimation Powderless DTF+

- Equipment

- Heat Transfer

- Alignment

- Sawgrass

- virtuoso

- Coastal

- transfer paper for shirts

- inkjet transfer paper

- heat press vinyl

- vinyl heat transfer

- types of ink cartridges

- types of printing inks

- types of printer ink

- sawgrass print manager

- how to connect sawgrass printer to computer

- sawgrass sg800 manual

- Pricing

- Business Success

- Coastal Business Supplies

- Profit

- easysubli instructions

- siser easy subli htv instructions

- sublimation ghosting

- ghosting in sublimation

- sublimation vs heat transfer

- sublimation paper vs heat transfer paper

- sublimation business ideas

- sublimation business plan

- sg500 sublimation ink

- sawgrass ink

- sawgrass sublijet-hd sublimation ink

- cricut mug press

- mugs for cricut mug press

- chromaluxe

- photo panels

- Ceramic Mugs

- Latte Mugs

- Production

- Expert

- Powderless DTF

- HTP

- Mug Packaging

- Wide Format Printing

- Printing

0 Comments

Leave a Comment