Orca DTF Powder Shaker – Efficient, Consistent, and Fast DTF Application

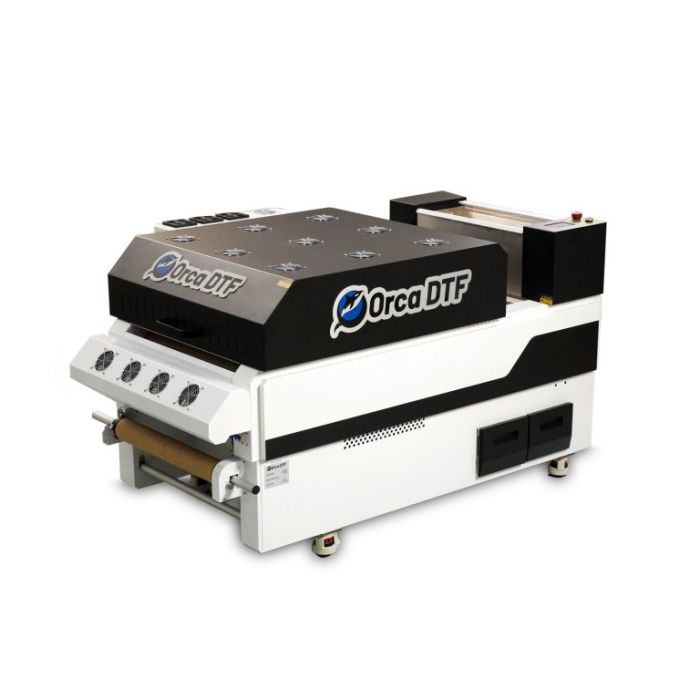

D620 Orca DTF Shaker Oven: Advanced Heat & Efficiency for Perfect Transfers

Experience seamless and precise Direct-to-Film (DTF) printing with the D620 Orca DTF Shaker Oven. Engineered for superior performance, this high-tech shaker and curing oven ensures flawless powder adhesion and consistent results on every print.

With its built-in shaker system and even heat distribution, the D620 delivers smooth, professional-quality transfers without the hassle. Whether you're handling large production runs or intricate designs, this shaker oven guarantees reliability, speed, and efficiency.

Perfect for businesses seeking enhanced printing outcomes, the D620 Orca Shaker Oven is a powerful addition to any DTF setup, providing long-lasting, high-definition prints every time.

*Image shown with printer and shaker.

Key Features -

- Automated Powder Shaking & Application: The integrated powder shaker applies adhesive powder evenly across your prints, reducing manual labor and ensuring perfect powder coverage for every job.

- High-Efficiency Curing Oven: With precise temperature control, the D620’s curing system guarantees thorough powder adhesion, creating crisp, detailed prints that stand up to washing and wear.

- Built-in Air Purifier: Equipped with an air filtration system, the D620 minimizes airborne particles and odors, ensuring a clean and safe working environment.

- Adjustable Conveyor Speed: Tailor the conveyor’s speed to match your production needs, allowing for smooth transitions between large runs or more detailed, custom prints.

- Compact & Space-Saving Design: While powerful, the D620 features a streamlined design that fits seamlessly into any workspace, making it ideal for businesses of all sizes.

- User-Friendly Interface: The intuitive control panel allows easy adjustments to temperature, speed, and powder application, ensuring optimal settings for every print job.

- Even Heat Distribution: Engineered with advanced heating elements, the oven ensures uniform heat across the entire print, preventing uneven curing and ensuring professional results every time.

Benefits -

- Consistent Results: The D620 ensures flawless, high-definition prints with every pass, perfect for both intricate designs and high-volume production.

- Reduced Maintenance: The built-in air purifier helps to prolong machine life by minimizing dust and debris buildup, while the high-quality components reduce downtime and the need for frequent repairs.

- Enhanced Productivity: Automated features such as the powder shaker and adjustable conveyor speed streamline your production process, allowing you to handle more orders with less effort.

Ideal for growing businesses or high-demand production environments, the D620 Orca DTF Shaker Oven takes your DTF printing to the next level, delivering fast, reliable, and top-tier results.

Switch to Smart, Switch to Innovation - Overview of the Orca D620 Features:

BUILT-IN REPLACEABLE AIR PURIFIER

This Orca DTF machine has added a new level of convenience and environmental consciousness with their Powder Shaker Machine. Engineered with an integrated air purifier, it ensures the air generated during the curing process is clean and pure. Better yet, the purifier is attached with a hinge, functioning like a door for effortless use and replacement. Elevate your printing system to a more sustainable, user-friendly experience with our Powder Shaker Machine.

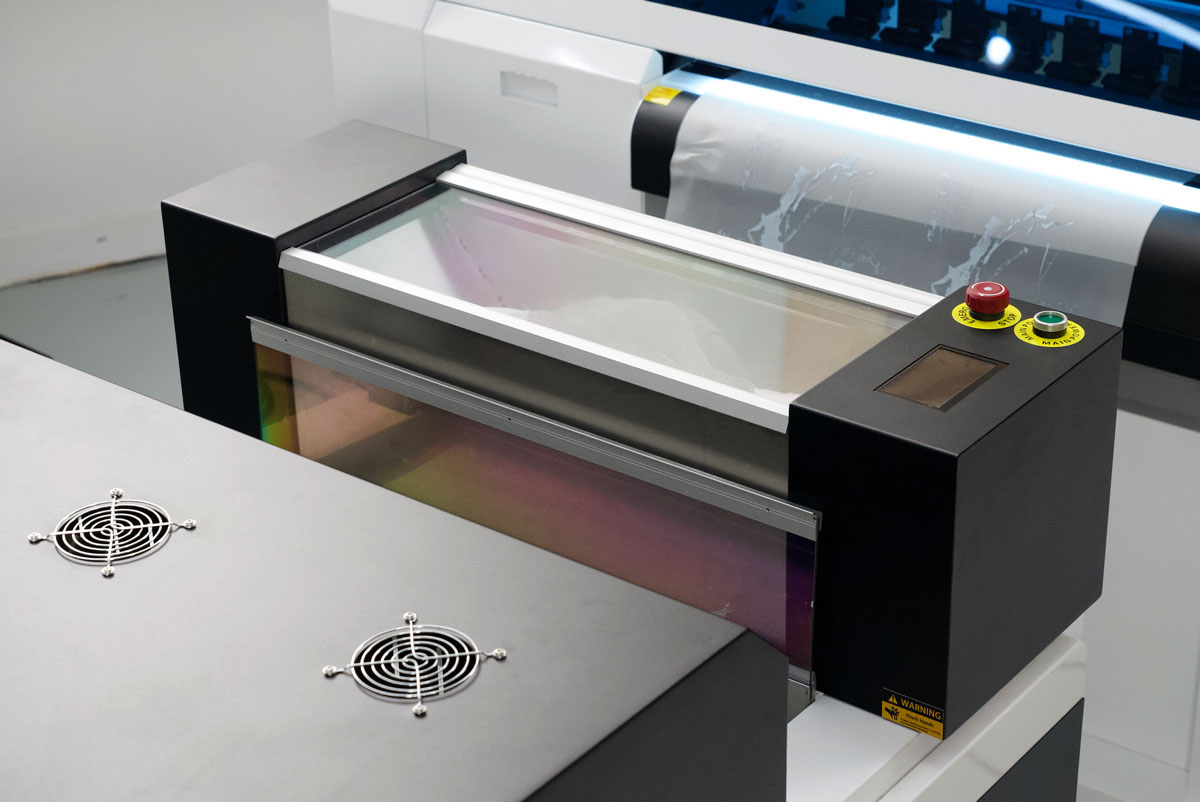

DOUBLE ROW OF HEATING LAMPS

Equipped with upper and lower double rows of high-efficiency heating lamps, the innovative design not only delivers superior curing results but also supports energy conservation. You can save up to 30% on your power consumption!

OPTICAL SENSOR

Enjoy the future of hassle-free printing with Orca's powder shaker's innovative feature - the optical sensor. This cutting-edge technology is designed to detect the printed film from the D620 printer and will automatically control the film feeding process in the shaker.

No more continuous monitoring required on your end! The sensor diligently does the job for you. When the printed film hangs below the sensor, it's smoothly fed into the shaker, ensuring a continuous operation. And the moment the film rises above the sensor, the feeding process halts, preventing wastage and ensuring optimal film use.

Specifications -

- Dimensions (L x W x H):

- 76″ x 45″ x 45″

- Weight:

- 520 lb.

- Maximum Film Width:

- 23.6″

- Electrical Requirements:

- AC 220V 30A 50/60Hz

Plug not included, Electrician Install recommended

- AC 220V 30A 50/60Hz

| Manufacturer | Orca |

|---|---|

| Print Applications | Direct-to-Film (DTF) |

| Printer Type | Direct-to-Film (DTF) |