Ink 101: The Ultimate Guide to Different Printer Inks

With all of the different technology in the garment and apparel decorating industry, it is easy to get lost in the midst of the hundreds of printers and inks available for use. From solvent to sublimation, the terminology can leave a lot of people confused. But don’t worry! To help make it easier to understand some of this industry jargon and prevent any misunderstandings, we’ve broken down the subject of inks and equipment to a simplified description of each ink system alongside its pros and cons.

Inkjet Inks

Inkjet inks are water-based, and they are most commonly found in the printers you’d find in offices and professional work places. Inkjet printers come with this type of ink, which is contained in cartridges and comprised of a certain pigment to water ratio (which keeps the ink a liquid). The ink is deposited on the paper during the printing process, and once printing is complete, the water evaporates off the paper leaving behind only the pigment. The four basic colors are CMYK (cyan, magenta, yellow and black) with some printers using additional colors. What is not as common knowledge is that there are two categories of inkjet inks: dye-based and pigment-based.

Dye-based inkjet inks are the most common inks that come with the average inkjet printer. The pigment is fully dissolved in water inside the cartridge. These inks are technically not ideal for heat transfer paper garment applications, as they tend to run more easily under wet conditions, but they are great for creating items such as documents, indoor displays, posters, or fine art photographic prints due to their vibrancy and true-to-color image reproduction.

Pigment-based inkjet inks (sometimes called UV inks) have larger pigment particles that are insoluble and are suspended in less water, which makes them ideal for more waterproof solutions. They perform well when used on heat transfer papers for garment decorating, window/outdoor displays, posters, decals, photographic prints, and more. The prints do not run when they come in contact with water, but they can fade and break down over time after repeated washing (specifically with heat transfer papers) or prolonged outdoor exposure. They are UV-resistant, which means they can be exposed to UV light and the colors will remain stable. Due to the nature of these inks and the way the light reflects off the pigment particles, they sometimes appear more muted in vibrancy than the dye-based inks. Some of the Epson inkjet models already come with pigment inks, but it is a good idea to double-check with the manufacturer if you are unsure.

Note: These are not to be confused with “UV-curable inks”, which require exposure to a very strong UV light to be cured onto the media.

|

Aqueous Dye-Based Ink |

Aqueous Pigment Ink |

|

|

PROS: |

• Lower Cost • Brighter / more vibrant print |

• More waterproof solution that will not run in contact with water • UV-resistant that promotes color stability when exposed to bright light • Great for heat transfer paper applications |

|

CONS: |

• Not waterproof – ink may run when in contact with water |

• Higher cost • Color may appear more muted / not as vibrant as dye-based ink • Can be prone to clogging if left inactive inside printer |

Laser Toner

The second most popular method for everyday printing is laser printing, which in fact does not use ink, but rather a very fine powder called “toner”. The toner is contained in large cartridges in the printer and then deposited on the paper through either laser or LED technology. After the laser toner is printed, the paper runs through a fuser which uses heat to fuse the pigment in place. Most laser printers use CMYK colors, but recent advances in technology now allow for select printers to use white toner instead of black toner. This includes the Crio models, such as the Crio 8432WDT.

Toner (unlike most other types of inks) does not incorporate liquid in any way, which makes it a very waterproof solution, but it is still prone to fading over time. Because toner requires heating and curing, it is crucial to have a printer with a fuser that runs no hotter than 350ºF or the paper adhesive can melt and jam. This makes the compatibility of papers and printers sometimes difficult to guarantee, which is why it’s always best to test papers first or consult with your paper vender to ensure the paper you’re using will run smoothly through the printer. Because the market is constantly evolving, manufacturers have started building printers with the heat transfer process in mind. Our selection of Crio and OKI models have been tested and are warrantied with most of our heat transfer papers.

|

PROS: |

CONS: |

| • Waterproof • Requires little to no maintenance, as toner does not clog • Faster print speed for high volume printing • Longer lasting • Costs significantly less per print |

• Laser printers not compatible with all papers, especially some heat transfer papers • Higher cost for full color and photographic printers • Bulkier / larger cartridges and printers • Not always ideal for quality fine art prints |

Dye-Sublimation Ink

Dye-sublimation ink, while also water-based, is a much different type of ink when compared to other typical printing solutions. Sublimation ink is printed on special sublimation paper (similar in look and feel to thick copy paper), which releases the ink once it is heat activated in the press, turning it from solid to gas while bypassing the liquid stage.

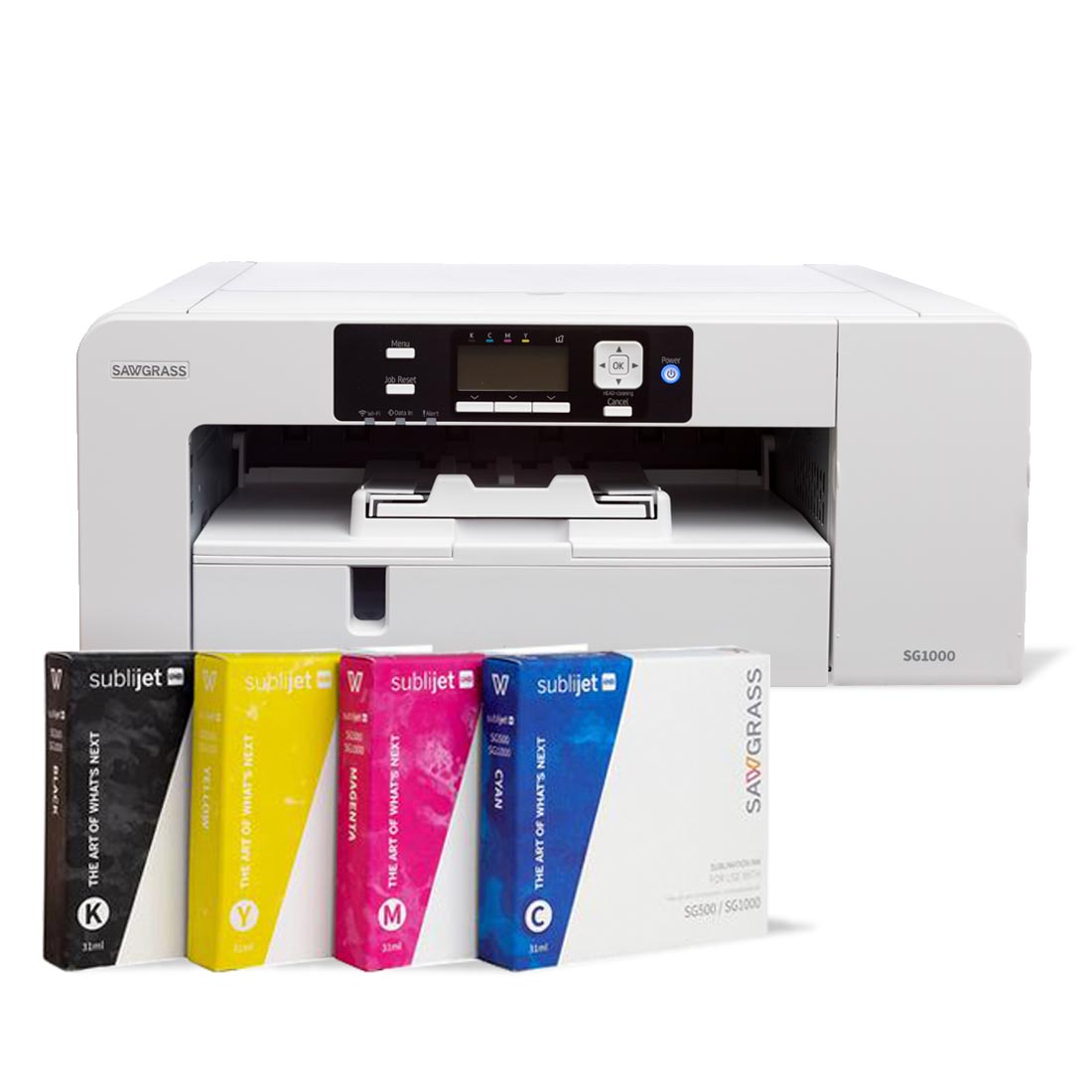

There are brands of dye-sublimation ink that are compatible with desktop sublimation printers, such as the Sawgrass SG500 and Sawgrass SG1000. Dye-sublimation ink is also available for wide format Epson and Mutoh printer models for those business owners who seek high volume production, larger printing areas and high cost savings (lower cost for ink overall). Dye-sublimation ink is so special in composition that it also requires specific color correction software to ensure performance consistency. Sublijet inks for Ricoh and Sawgrass printers are reformulated into a gel-like substance (uses less water), which prevents clogs when printer is not being used daily. However, these ink types only come in cartridges and are not available for a bulk system.

The process of sublimation transfer printing and pressing is usually carried out at around 370-400ºF depending on the item. The process ends as soon as heat is no longer applied and the substrate starts cooling down. Sublimation ink actually dyes the product on a molecular level rather than sitting or transferring just on top of the item, which results in a permanent solution under normal conditions. Since the sublimation ink can be activated at really high heat at any point, it is important to transfer a full design from a single sheet of paper in a one-step process. The ink can be activated at temperatures as low as 340ºF (and sometimes even lower), and it has the ability to permanently stain equipment or already pressed items.

Because sublimation is an additive color process and it actually changes the color of the item, it is generally only compatible with white or very light substrates, as the color of a non-white shirt will bleed into the image. Items that are black will block an image out entirely, so sublimating onto black T-shirts is not possible at all. It is best compatible with 100% polyester garments and poly-coated items. Other blends of polyester will typically work, but only the polyester content will be dyed (i.e., 50/50 blends of poly/cotton will turn out half as bright as a 100% polyester garment). Sublimation does not work on natural fibers (cotton, rayon, wool, etc.), as the ink will wash out of the items completely. Dye- sublimation inks will not transfer on non-coated items.

|

PROS: |

CONS: |

| • Permanent transfers that last as long as the garment/item • Easy and fast set up and transfer process Transfers realistic full-color photographs and designs with high detail • No texture of its own, easy to transfer on variety of coated items such as mugs coasters, mouse pads, ornaments and more |

• High cost on inks • Only compatible with 100% polyester or sublimation coated items that are white/light • Requires some design software/printer set up for proper color control |

Solvent Ink

Solvent ink is a more aggressive type of ink, available specifically for standing professional style printers with an inkjet style printhead, and is typically used mostly for outdoor applications due to its ability to adhere to a wide variety of media and vinyls and incredible durability. It is great for sign/banner vinyls, T-shirt vinyls and wallpaper media among others. The pigment is dissolved in a solvent chemical instead of water, which evaporates once it has been printed. Its chemical makeup makes it waterproof, fade-proof and scratch resistant in most weather conditions and lasts as long as the material it is printed on. However, due to its caustic nature, it is only compatible with special solvent inkjet printers.

Solvent ink is technically available in two different styles, though both are incredibly similar to one another (similar to pigment vs. dye-based ink differences):

Traditional solvent– This ink has a stronger chemical makeup which allows it to dry faster and penetrate deeper into a wider variety of media that doesn’t necessarily need to be coated. However, since the solvent chemical evaporates once it has been printed, it can cause hazardous fumes that can be inhaled by humans. Proper ventilation and space are required for this type of ink.

Eco-solvent– “Eco” refers to the lower hazard level this ink is for humans. Eco-solvent inks use a solvent that is not as aggressive, usually derived from mineral oil, and is better suited for indoor environments that don’t have a special air ventilation in place. The tradeoff however is slower drying times, with anywhere from a few seconds up to 12 hours of drying time depending on the media. This is becoming less of an issue with certain vinyls being added to the market, such as our ColorPrint Easy vinyl for garments which dries instantly.

|

Traditional Solvent Ink |

Eco-Solvent Ink |

|

|

PROS: |

• Faster drying times • Waterproof, scratch-resistant and fade-proof • Harsher chemical allows for printing on wider variety of media such as uncoated vinyl/banner material • Low costs for inks |

• Waterproof, scratch-resistant and fade-proof • No odor and made with biodegradable chemicals that are not as hazardous • Can be used in smaller indoor spaces • Low cost inks |

|

CONS: |

• Hazardous fumes require proper ventilation and large working space • Requires proper disposal and handling |

• Slower drying times • Not compatible with as many vinyls/materials |

Latex Ink

HP Latex printers are similar to solvent and eco-solvent printers in that they are most often used for producing sign vinyl, wallpapers and decals, but they are also capable of printing on textiles, which enables users to produce items like wallcoverings, canvas, and window blinds..

HP Latex Inks are better for both the operator and the environment than solvent and eco-solvent inks – in fact, they are ECOLOGO Certified, UL GREENGUARD GOLD Certified, and ENERGY STAR® Certified up to a fully decorated room (360 ft²). This allows you to go where solvent cannot, such as healthcare environments. Latex printing allows users to print responsibly while still maintaining reliable and consistent results.

Additionally, just like eco-solvent inks, there is no ventilation process necessary – in fact, your prints come out of the printer completely dried and cured (whereas eco-solvent can take hours to dry). HP Latex Inks are also naturally resistant to the elements, effectively making them scratch-resistant, waterproof, and chemical/light/fade-resistant. Another huge benefit of HP Latex Inks is that their printheads are easily replaceable by the user at a fraction of the cost of solvent printheads; there's no need to hire an onsite technician to replace your printhead!

Direct-to-Garment Ink

Direct-to-garment (DTG) printing is a process in which ink is applied directly onto 100% cotton fabric through a flatbed printer (our go-to DTG printer is the Epson SureColor F2100). These inks are water-based and similar to pigment-based aqueous inks. They come in the standard yellow, magenta, cyan, black, and white colors. Once printed, they are permanently cured with heat. Due to the DTG inks printing wet, the best way to cure the garment is to either send the item through a pre-heated oven or hover a heat press over the garment with little to zero pressure. DTG prints feel similar to a screen print and can last the lifetime of the garment.

White or very light-colored fabrics don’t need any pretreatment prior to printing. However, since the DTG ink absorb into the fabric, it would be difficult for a print to stand out on dark garments. For dark T-shirts, the DTG printer will first print a solid white base to create a foundation for the colored DTG inks to sit on top of. This creates a heavier print with the additional layer of white ink added into the mix (titanium oxide is its main makeup, which already makes it heavier), and it can cause the ink to bleed through the fabric. To prevent this from happening, dark or black garments are coated with a pretreatmeant solution by hand or using a machine. The transparent pretreatment coating also helps the white ink adhere better to the fabric. After printing, the extra pretreatment solution on the shirt dissolves in the wash, leaving the shirt with a clean and bright print.

DTG inks are most compatible with 100% cotton or 100% ringspun cotton only. In some instances, you can get away with printing cotton/poly blends, but your results may appear slightly faded or distressed. You cannot print with DTG inks on 100% polyester because it is a plastic material, which does not allow for ink absorption. With an average amount of washing, the print will fade dramatically over time. That being said, DTG may be used for cotton-based, polyester-coated items, such as mouse pads and flip flops, for display purposes.

|

PROS: |

CONS: |

| • Waterproof, fade proof and scratch resistant • Produces high quality prints and allows for photographs, gradients and shadows • Very soft and durable (should last the life of the garment) • Great vibrancy and detail |

• Printer requires monthly maintenance and upkeep • RIP software required, with specific settings that need to be calibrated for different fabric weaves and thickness • Black or brightly colored fabrics require pre-treatment which makes for a longer process and potential higher costs for pretreatment solution and machine • Compatible with 100% cotton fabric only and some cotton/poly blends |

Technology is constantly evolving and improving, and there may be other types of inks for printing methods that weren’t included in this blog. This list is compiled to represent inks that we offer to our customers on a regular basis and are capable of providing great support over phone, e-mail or chat!

If you have questions or need advice about which type of ink is right for your business, drop us a line at 800-562-7760 or shoot us an email at [email protected] to talk with one of our Product Specialists – we’d be more than happy to lend you a hand!

0 Comments

Leave a Comment