Fix Wide-Format Printing Bottlenecks in 5 Steps

5 Common Workflow Bottlenecks with Wide-Format Printers (And How to Fix Them)

Did you know? In most print shops, up to 60% of wide-format printer downtime happens before the first print starts. Prepress, finishing, and media interruptions are silent killers of productivity. Labor shortages and manual scheduling often make things worse. The good news? Every one of these bottlenecks has a fix.

By the end of this guide, you’ll know exactly where bottlenecks hide—and how to free your workflow so your printers work smarter, not harder.

1.Prepress & RIP Delays – The Invisible Time Thief

Why prepress eats up more time than you think

Files arrive with missing fonts, oversized images, or improper color profiles. Your RIP stalls while your client wonders why the “fast printer” is taking hours.

Fix: Preflight automation & smarter RIP setup

- Preflight software catches errors automatically.

-

What is preflight software? Preflight software is a tool used in the printing and graphic design industry to check digital files (usually PDFs) for potential issues before sending them to print. The goal is to “pre-flight” a job, like a pilot’s preflight checklist, so everything is correct and print-ready.

What it does:

-

Checks for errors such as missing fonts, low-resolution images, incorrect color profiles, or unsupported file formats.

-

Verifies technical specifications like bleed, trim size, spot colors, transparency, and overprints.

-

Flags problems early so they can be fixed before costly mistakes happen in production.

-

Ensures print compliance with industry standards (e.g., PDF/X, ISO standards).

Common Uses:

-

Print shops use preflight software to make sure client files are ready for offset, digital, or wide-format printing.

-

Designers and publishers use it to check files before sending them out, preventing reprints and delays.

-

-

- Batch processing prevents manual delays.

- Invest in RIP software with faster rendering power.

-

RIP software (short for Raster Image Processor) is specialized software that converts digital files (like PDFs, TIFFs, or PostScript files) into a rasterized format (bitmap) that printers can understand and output. It’s a crucial step in professional printing because printers can’t directly interpret complex design files.

What RIP Software Does

-

Translates digital files into printable data (bitmaps) that match the printer’s resolution.

-

Color management – ensures accurate color reproduction using ICC profiles, spot colors, and ink control.

-

Job management – handles multiple files, nesting, tiling, scaling, and print queues.

-

Print optimization – reduces banding, sharpens images, and optimizes ink usage.

-

Advanced features – like variable data printing, step-and-repeat layouts, or specialty ink handling (white, metallic, varnish).

Why It’s Important

-

Guarantees high-quality, consistent prints.

-

Saves time by automating file preparation.

-

Minimizes errors (wrong colors, missing elements, file corruption).

-

Essential for large-format, textile, screen printing, DTG, and signage printers.

-

-

Tip: Many wide format printing problems can be solved by standardizing file requirements and preflighting before they reach production.

2. Finishing Bottlenecks – When Fast Printing Meets Slow Cutting (Ideal for large-scale production runs, like mugs)

Why finishing becomes the choke point

Your printer can run 24/7—but trimming, and possibly taping can cause a backflow. This causes stacks of unprocessed prints piling up.

Fix: Balance production flow

- Add a second unit if possible.

- Stagger print jobs based on finishing time.

- Automate repetitive cutting or taping tasks.

Address print production bottlenecks by matching print and finishing speeds.

3.Media & Consumable Interruptions – The Hidden Cost of Downtime

Everyday issues operators hate to admit

- Roll jams or paper running out mid-print

- Nozzle clogs

- Ink running out mid-print

- Poor stacking (prints curling)

Fix: Preventive maintenance + smart supplies

- Clean nozzles proactively - check daily before production runs!

- Track ink usage - always keep extra ink on hand.

- Check printer for any alerts before start of production runs.

- Check paper on roll to ensure print(s) can run without paper running out.

Tip: Avoid common printer issues in wide format by storing rolls flat and maintaining humidity control.

4. Scheduling & Job Costing Chaos – When Every Minute Counts

Why manual scheduling fails

Print shops juggle dozens of deadlines. Without a centralized system, jobs overlap, materials run out, and clients face delays.

Fix: Workflow Software / Integrations - Most RIP Software's Offer This!

- Schedule production runs ahead to avoids conflicts.

- Real-time cost tracking improves profitability.

- Inventory alerts stop last-minute surprises - most printers offer this.

Insight: Printing workflow challenges increase downtime without integrated software.

5.Labor & Automation Gaps – The Skills Shortage Problem

What labor shortages mean for print shops

Skilled operators are hard to find. Manual tasks like nesting, preflighting, or trimming slow down production when teams are stretched thin.

Fix: Automate the low-value, repeatable tasks

- Automated Software for wide format printing will making printing easy - drag/drop, auto nest, auto mirror (if applicable).

- Integrated print-to-process finishing workflows

- Upskill staff to handle overseeing print jobs and end quality

Automation doesn’t replace people, it frees them for higher-value work.

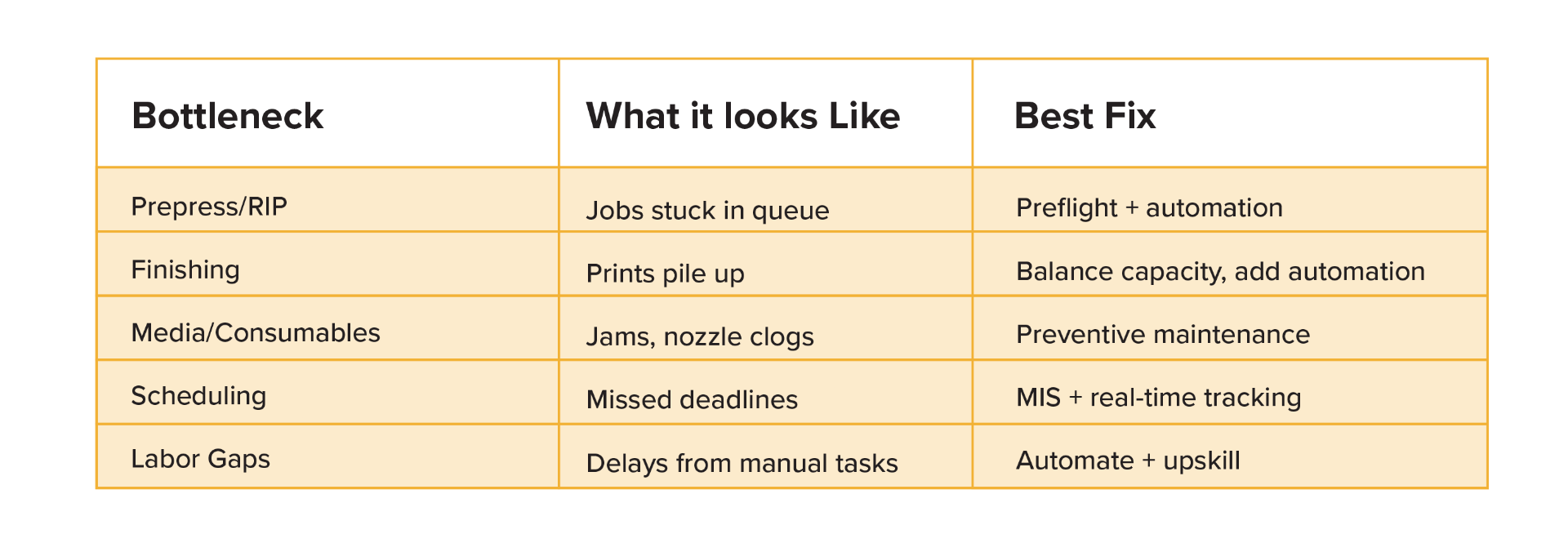

Bottleneck → Solution Table

From Bottlenecks to Breakthroughs

From Bottlenecks to Breakthroughs

You don’t need brand-new printers to fix bottlenecks. Often, smarter workflow and automation are the keys. Identify your weakest link—and fix it first.

0 Comments

Leave a Comment