White Toner Transfer – The “Other” DTF

Are you considering investing in printing technology that can produce high-quality, full-color prints on a variety of surfaces? If so, you’ve probably come across two of the most popular options – white toner transfer printers and Direct-to-Film printers, best known as DTF. While both printing technologies can produce stunning prints, they differ in terms of their capabilities and cost-effectiveness.

In this blog post, we will provide an in-depth comparison of both decoration technologies. We will explore the unique features of each printing technology, their suitability for different applications, and the costs involved in using them. By the end of this blog, you will have a better understanding of the pros and cons of each option, allowing you to make an informed decision about which technology is best for your specific business needs.

Direct-to-Film Printing

Direct-to-Film is an innovative technology in heat-transfer based printing. It involves printing designs with dye or pigment-based ink on a transparent film, which is then coated with hot-melt adhesive powder and transferred with a heat press to the final substrate. DTF printers are made for high-volume production printing and cost around $15,000+ for an entry level system. The powdered adhesive required for this type of transfer needs to be applied manually or with shaker equipment. Some DTF printers come with shakers while others don’t, which may require an additional expense.

How Do DTF Printers Work?

DTF printers are equipped with five colored ink tanks, CMYK+White. The DTF printers utilize a print head to spray micro-droplets of ink onto the film, replicating the design sent from the RIP software in digital form. The DTF printer ink is specifically designed for this process to ensure optimal results so that final designs precisely depict the desired image on the fabric. These are especially useful for dark colored garments, where the white ink acts as a base, allowing the colors to be vibrant.

Maintenance – Daily (regardless of whether the printer is operating or not)

However, DTF printers require daily maintenance to run smoothly, such as cleaning the print head regularly to prevent nozzle clogging. Sometimes air bubbles in the ink cartridge can block the nozzle. The white ink also needs to be continuously recirculated to keep it from coagulating, so it stays in fluid form. Unfortunately, the regular maintenance process can get very tedious and if it is not done correctly, it can affect the printer’s performance and lifespan.

Adhesive Powder

The Direct-to-Film adhesive powder is a white granular adhesive substance that binds the colored pigments from the printer to the surface being printed on. It is available in various grades specified in microns, allowing for distinct levels of thickness and performance in the DTF printing process.

Further precautions must be taken during the heating process or when heat fusing DTF powder to the printed sheet. These precautions include ensuring proper ventilation, employing air filtration systems, utilizing fume exhaustion methods, and wearing appropriate protective gear. Many DTF systems utilize thermoplastic polyurethane (TPU) based powders, and TPU manufacturers have reported that these powders may release MDI (methylene diphenyl diisocyanate) vapors when heated at elevated temperatures.

Health organizations such as OSHA (Occupational Safety and Health Administration), the EPA (Environmental Protection Agency), and the CDC (Centers for Disease Control and Prevention) have determined that exposure to MDI vapors can cause serious health issues, including respiratory impairments. Consequently, businesses must exercise great caution when working with TPU-based DTF powders and ensure that appropriate safety measures are in place to minimize the risks associated with MDI vapors.

Applications

DTF transfers can be applied on a wide range of fabric including, cotton, nylon, treated leather, polyester, 50/50 blends and more (light and dark fabrics). It is often recommended to switch powdered adhesive colors from white to black when transferring to dark garments.

Pros

- Ideal for high-volume production

- Low cost per print

- DTF transfers can be applied to any type of fabric

- High-resolution, detailed, and vibrant prints

- Great washability, durability, and elasticity

- Accepts rolls of transfer film to print

Cons

- Slow printing – Single head units up to 50 full front transfers per hour

- Requires daily maintenance

- Higher cost of entry

- Large space requirements

- Most units require 220v power

- Unknown health risks of powdered adhesive

- Higher learning curve to get started

- 1-Year Warranty / 6-12 Months on Printhead(s)

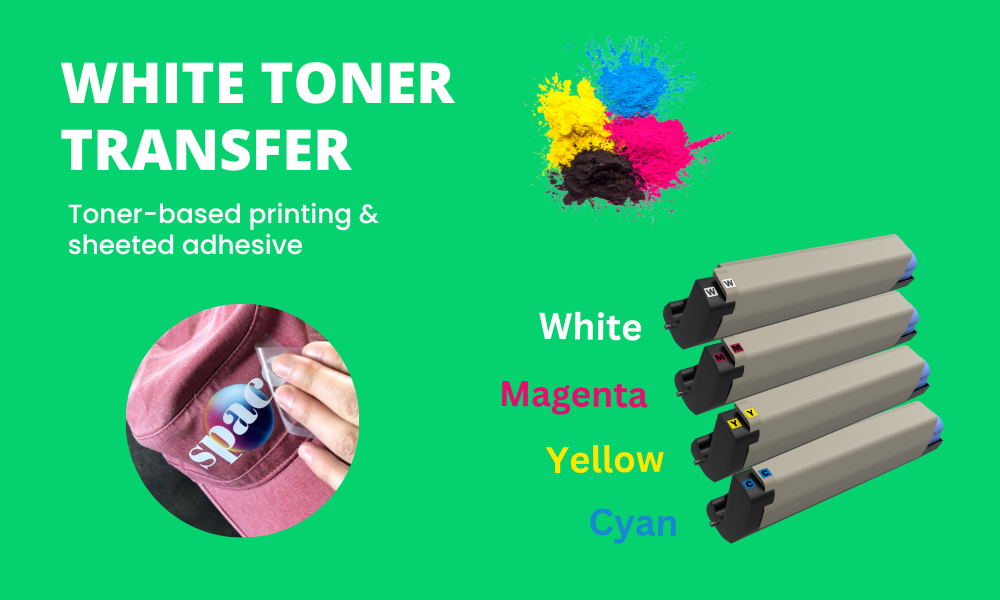

White Toner Transfer Printing

White toner transfer is also a heat-transfer based printing process. Unlike ink based DTF printers, this technology uses a laser-based toner printing process that prints the design to a special paper or film that is then transferred onto a desired substrate. White toner printers are ideal for short run to small volume production runs. The additional white toner layer acts as an under base that enables producing vibrant and opaque designs on a wider range of substrates. In comparison to the A4 or 11x17 DTF printers mentioned above, white toner transfer printers in this size run about $8,000.

How Do White Toner Transfer Printers Work?

Depending on the model, white toner printers come with four or five color toner stations – CMY+White or CMYK+White. In case that you want to print black in a CMY + White unit, the CMY creates a composite black that resembles the black produced in offset printing. White toner printers utilize dry powdered toner instead of liquid ink. They produce electrostatically charged dots on a light-sensitive drum which attracts toner powder. The toner is transferred to the paper or film which is then adhered to the surface by a heating element called a fuser. White toner printers produce high-resolution images with vibrant colors to precisely replicate designs, ensuring a premium finished product.

No Maintenance

Completely opposite of DTF printers, white toner printers do not require daily maintenance. In fact, you can turn the white toner printers off, leave them to sit for a year, turn them back on and get outstanding finished results. With toner-based systems, there are no head strikes, nozzle clogs, or line stops. The absence of liquid ink in white toner transfer printers provides added convenience and flexibility with trouble free operation. A DTF printer would require several hours of maintenance and money for repairs.

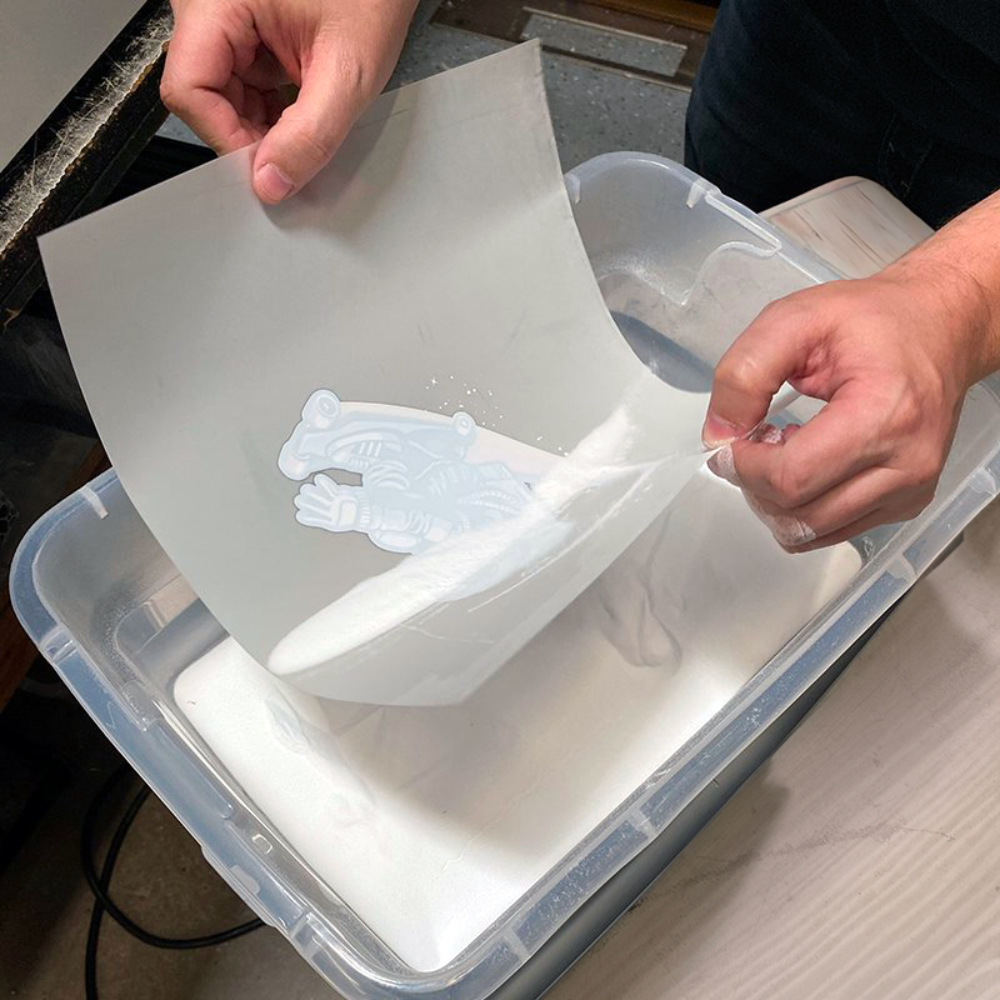

Sheeted Adhesive

White toner paper and film use a sheeted adhesive to adhere the transfer to the substrate. For light colored garments and hard surface papers, the adhesive is embedded in the sheet that runs through the printer. This is called “One Step” process. For dark colored garments, it requires a “Two Step” process, where the printed sheet is “married,” or heat pressed to the adhesive sheet. The adhesive is only applied to where there is toner, so there is no concern for excess adhesive being transferred. Once the adhesive sheet is removed from the printed sheet as a hot peel, the printed sheet with the adhesive is ready to be transferred to the garment or substrate of your choice.

Applications

White toner transfers can be applied to the widest range of substrates over any other single decoration method, even non-heat applied materials. This is accomplished through papers or films that are designed to be transferred on specific materials. This includes any type of fabric, hard surface, glass, wood, metal, acrylic, mylar (even balloons), candles, plastics, and more. Not only can you create beautiful designs to transfer to other materials, but you can also print directly on specific products such as paper (including card stock), window cling, stickers, etc. This allows you to open additional revenue streams, increasing sales opportunities and profit.

Pros

- No Maintenance

- Faster printing – 540 full front transfers per hour

- Ideal for short run single and full color production

- Small space requirement (no bigger than desktop printer)

- High-resolution, detailed, and vibrant prints

- White toner transfers can be applied to any type of fabric, hard surface or other substrate including mylar, wood, metal, acrylic and more

- Lower cost of entry

- Safe sheeted adhesive

- Minimal training to get started

- 2-Year Onsite Warranty / 5-Years on LED Heads

Cons

- Higher cost per print

- Requires a high-quality heat press

- Transferring to dark-colored garments requires two-step process, which can present a learning curve to get the marrying process down correctly

- Requires final 30 second press with a special silicone sheet to seal the toner to garments only

In Conclusion

When comparing white toner transfer and DTF printing technologies, both have strengths and limitations.

White toner transfer printing is an excellent choice for printing on the widest variety of substrates, producing vibrant and durable prints with minimal experience, setup time and cost. It is ideal for small to medium-sized production runs.

DTF printing offers exceptional color accuracy and is suitable for a wide range of fabrics. It is ideal for high-volume production environments that run the printer daily. However, it requires more setup time and training with a larger initial investment in equipment and supplies.

Both decoration methods have their place in the market. It really comes down to cost of entry, volume of production runs, and maintenance. Ultimately, the choice between white toner transfer printing and DTF printing will depend on your specific needs and budget. We recommend considering factors such as the type of surface you will be printing on and the size / quantity of prints you need to produce. By carefully weighing these factors and understanding the unique capabilities of each technology, you can make an informed decision that will result in high-quality and cost-effective prints.

0 Comments

Leave a Comment