Heat Transfer Guide: Find the Perfect Transfer Every Time

Choosing The Right Heat Transfer Just Got Easier!

When it comes to creating standout apparel, the type of heat transfer you choose can make or break your project. Whether you're working on a single custom shirt or fulfilling a large order, selecting the right heat transfer for your needs is key to achieving a professional finish. Our Heat Transfer Guide is designed to take the guesswork out of the equation so that you can confidently match the ideal transfer to your project every time.

Why Heat Transfers? The Basics of Heat Transfer Printing

Heat transfer printing uses a combination of heat, pressure, and specialized transfer materials to transfer designs onto various surfaces, typically garments. This versatile technique offers a range of benefits:

- Vibrant Color Reproduction: Perfect for multicolor designs.

- Affordable for Small Runs: Great for one-offs or limited orders.

- Durable Results: Long-lasting and holds up well through washes.

With different types of transfers available, it’s essential to understand which one aligns best with your project, design complexity, and production scale.

Key Factors in Choosing the Right Heat Transfer

To select the perfect transfer, consider these key factors:

- Design Complexity: More colors and intricate details may require special transfer types.

- Garment Type: The fabric, texture, and color can impact which transfer works best.

- Production Quantity: Some transfers are better for bulk orders, while others suit small runs or single items.

- Durability Needs: Higher durability transfers are ideal for activewear or heavy-use items.

- Budget: Some methods are more economical for large quantities, while others remain cost-effective for smaller projects.

Heat Transfer Types: Find the Right Fit for Your Project

1. Heat Transfer Vinyl (HTV)

Best For: Single items, small batches, simple designs, text-based graphics

HTV is a popular choice for small format creators, as it’s easy to work with and can be cut into various shapes and designs. Great for single-color designs or layering, HTV works well on cotton, polyester, and blends.

2. Sublimation Transfers

Best For: Polyester garments, light-colored fabrics, high-detail designs

Sublimation is the go-to method for vibrant, full-color designs on white or light-colored polyester garments. Perfect for high-quality, long-lasting prints, this method creates a soft, “no-feel” finish.

3. Screen Printed Transfers

Best For: Large runs, multicolor designs, heavy fabric items

Screen printed transfers combine the durability and look of traditional screen printing with the ease of heat application. Ideal for bulk orders, they work well on a variety of fabrics and are especially cost-effective for large quantities.

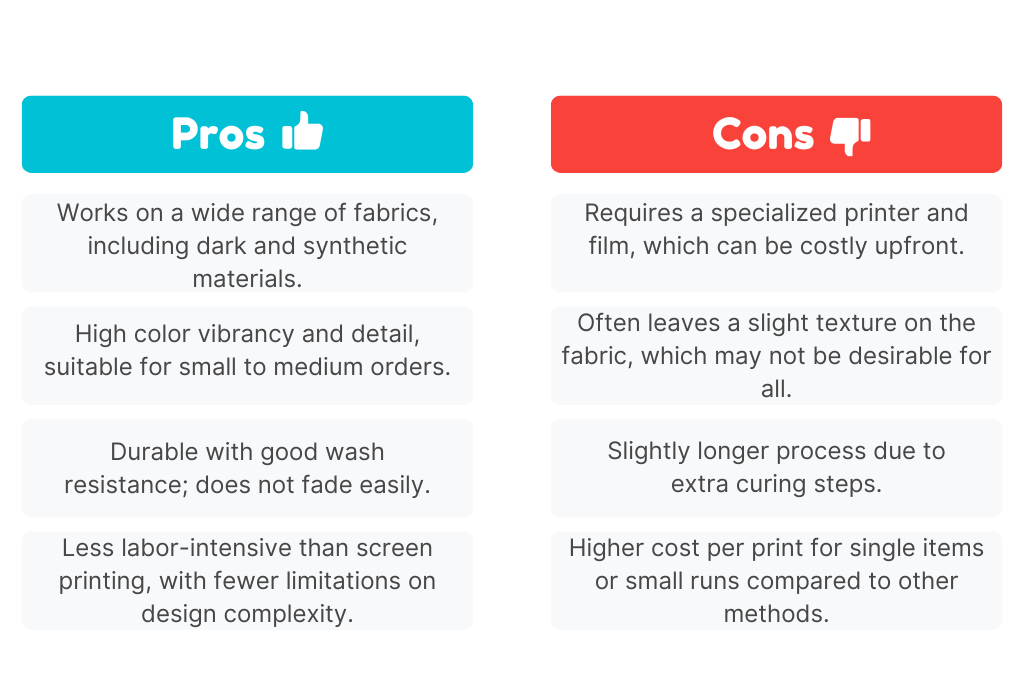

4. Direct to Film (DTF) Transfers

Best For: Various fabrics, including dark garments, small and medium runs

DTF is a newer technology that prints directly onto a special film and then transfers onto fabric. This method works on both light and dark materials and is compatible with a wide range of fabrics.

5. Direct to Garment (DTG) Printing

Best For: Small to medium runs, highly detailed and multicolor designs, cotton and cotton-blend garments

Direct to Garment (DTG) printing uses a specialized inkjet printer to apply ink directly to fabric, making it ideal for highly detailed, vibrant, and full-color designs. DTG is well-suited for small to medium-sized orders, especially if you’re looking to create custom designs with complex details and multiple colors. Unlike heat transfers, DTG printing doesn’t add a layer on top of the fabric, giving the print a soft and breathable feel.

Selecting the Right Transfer: Match Your Design & Order Size

Use the diagram below to determine the best heat transfer method based on the size of your order and the complexity of your design:

Tips for Successful Heat Transfers

- Preheat Garments: Preheating helps remove moisture, ensuring better adhesion and a smooth surface.

- Select Proper Heat Settings: Follow the recommended temperature and pressure for each transfer type.

- Use Heat Resistant Tape for Positioning: Helps keep transfers in place during pressing, reducing alignment issues.

- Test Press on Scrap Fabric: Especially helpful for new transfer types or techniques.

Achieve Picture-Perfect Results Every Time

By choosing the right heat transfer type for your project, you’ll achieve consistent, professional-quality results. Experiment with different methods to see what best fits your brand and business goals, and let our Heat Transfer Guide be your go-to resource.

Ready to get started? Explore our range of heat transfer products and let’s bring your designs to life!